Farm Season Preparation How to Quickly Configure Your Agricultural Machinery Operation System

As peak farming season approaches, time is money. Every day of delay in planting, cultivating, or harvesting can reduce yields and profits. For international buyers sourcing agricultural machinery from Chinese manufacturers, planning ahead and configuring equipment correctly is the key to smooth operations. This article explains how to quickly set up your agricultural machinery operation system, what combinations work best for different crops, and how to avoid common pitfalls.

We will also answer frequently asked questions from farmers and equipment managers to help you make informed decisions for a successful season.

Why Timely Configuration Matters

In modern agriculture, machinery downtime during peak season is more than an inconvenience—it’s a direct loss of income. Proper pre-season preparation reduces unexpected breakdowns, ensures efficient fuel use, and maximizes operator safety. A well-configured system also enables faster field operations and reduces manual labor costs, which is particularly important when labor shortages are common.

Chinese manufacturers have become leading suppliers of integrated farm machinery solutions worldwide, offering everything from compact tractors to precision seeders and sprayers. Leveraging these solutions can help farmers quickly scale up operations and meet tight seasonal windows.

Assess Your Farm Needs

Before configuring your system, evaluate your farm’s size, crop mix, soil type, and labor availability. Different farms require different machinery sets:

• Small mixed farms: Compact tractors with interchangeable implements.

• Medium-size grain farms: Mid-range tractors, seed drills, and sprayers.

• Large commercial operations: High-horsepower tractors, combine harvesters, and precision GPS systems.

Knowing your needs allows you to prioritize which machines to deploy first and which can be rented or outsourced during peak load.

How to Quickly Configure Your Agricultural Machinery System

1. Inventory Check: List all available equipment and note their operational status. Schedule maintenance for machines showing wear.

2. Implement Matching: Ensure tractors are matched with the right horsepower requirements for implements like plows, harrows, or planters. Over- or under-powered combinations waste fuel and time.

3. Optimize Field Workflow: Plan the sequence of operations—tillage, seeding, fertilizing, spraying—so machines do not sit idle waiting for another task to finish.

4. Staff Training: Train operators on any new equipment or technology, especially GPS guidance or variable-rate application tools.

5. Spare Parts and Fuel Stocking: Keep essential spare parts, filters, and lubricants on hand to avoid downtime during critical days.

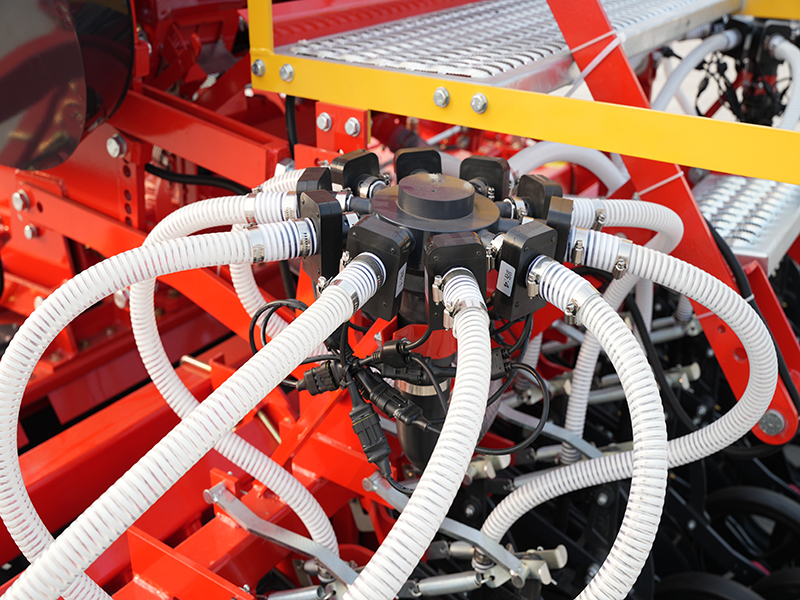

Integrating Smart Technology

Modern machinery increasingly includes telematics, sensors, and data analytics. Chinese manufacturers now offer affordable GPS auto-steering systems, yield monitors, and remote diagnostics. These tools not only improve accuracy but also allow managers to track machine utilization and predict maintenance needs—vital for busy seasons.

Frequently Asked Questions

Q1: Can equipment from different brands be integrated into one operation system?

A: Yes. Many implements follow standard hitch and hydraulic configurations. However, electronic systems (like ISOBUS) should be checked for compatibility or use adapters.

Q2: How early should I order new machinery from China for the upcoming season?

A: Ideally 3–6 months before peak season to account for production, shipping, and customs clearance. Some manufacturers offer priority production for repeat customers.

Q3: What’s the best way to reduce breakdowns during peak season?

A: Preventive maintenance. Replace worn parts, update software, and test all machines before fieldwork begins.

Q4: Are financing or leasing options available for imported machinery?

A: Many Chinese manufacturers partner with international financing institutions or offer staged payments, especially for large orders.

Q5: How can I train operators on new equipment without delaying fieldwork?

A: Request online training materials or pre-season workshops from the manufacturer. Some provide on-site technicians for initial setup and training.

Case Study Eastern European Grain Farm

A 1,500-hectare grain farm in Eastern Europe faced labor shortages during the planting season. By working with a Chinese agricultural machinery exporter, the farm deployed an integrated system of high-horsepower tractors, precision planters, and smart sprayers. With pre-season configuration and operator training completed a month ahead, the farm planted 20% more acreage in the same time, reduced fuel consumption by 15%, and reported fewer breakdowns.

Best Practices for International Buyers

• Choose a Supplier with Export Experience: Ensures smoother logistics and documentation.

• Request Customization: Machines can be adapted for local crops or field conditions.

• Verify After-Sales Support: Availability of spare parts and service centers.

• Plan Logistics Early: Account for shipping times and port congestion.

• Leverage Manufacturer Expertise: Many Chinese manufacturers offer free farm layout planning or machinery matching services.

Looking Ahead Sustainable Farming Solutions

Future farm machinery systems will integrate renewable fuels, electric drives, and autonomous operation. Chinese manufacturers are investing in electric tractors, AI-driven planting systems, and modular implements that can switch tasks quickly. Buyers who adopt these technologies early will gain a competitive edge in productivity and sustainability.

Conclusion

As the busy farming season arrives, a well-configured agricultural machinery operation system is crucial for success. By assessing farm needs, matching equipment properly, integrating smart technology, and partnering with experienced Chinese manufacturers, farmers can maximize uptime, reduce costs, and improve yields. Planning ahead transforms the stress of peak season into an opportunity for growth and efficiency.

5. Get Your Personalized Solution Now

→ Call the selection hotline: +86 158 5359 8030 (also supports accessory customization inquiries).